The aquaculture industry is evolving quickly. New environmental standards, advances in fish health management, and growing expectations from markets are encouraging producers to explore technologies that offer more control and predictability.

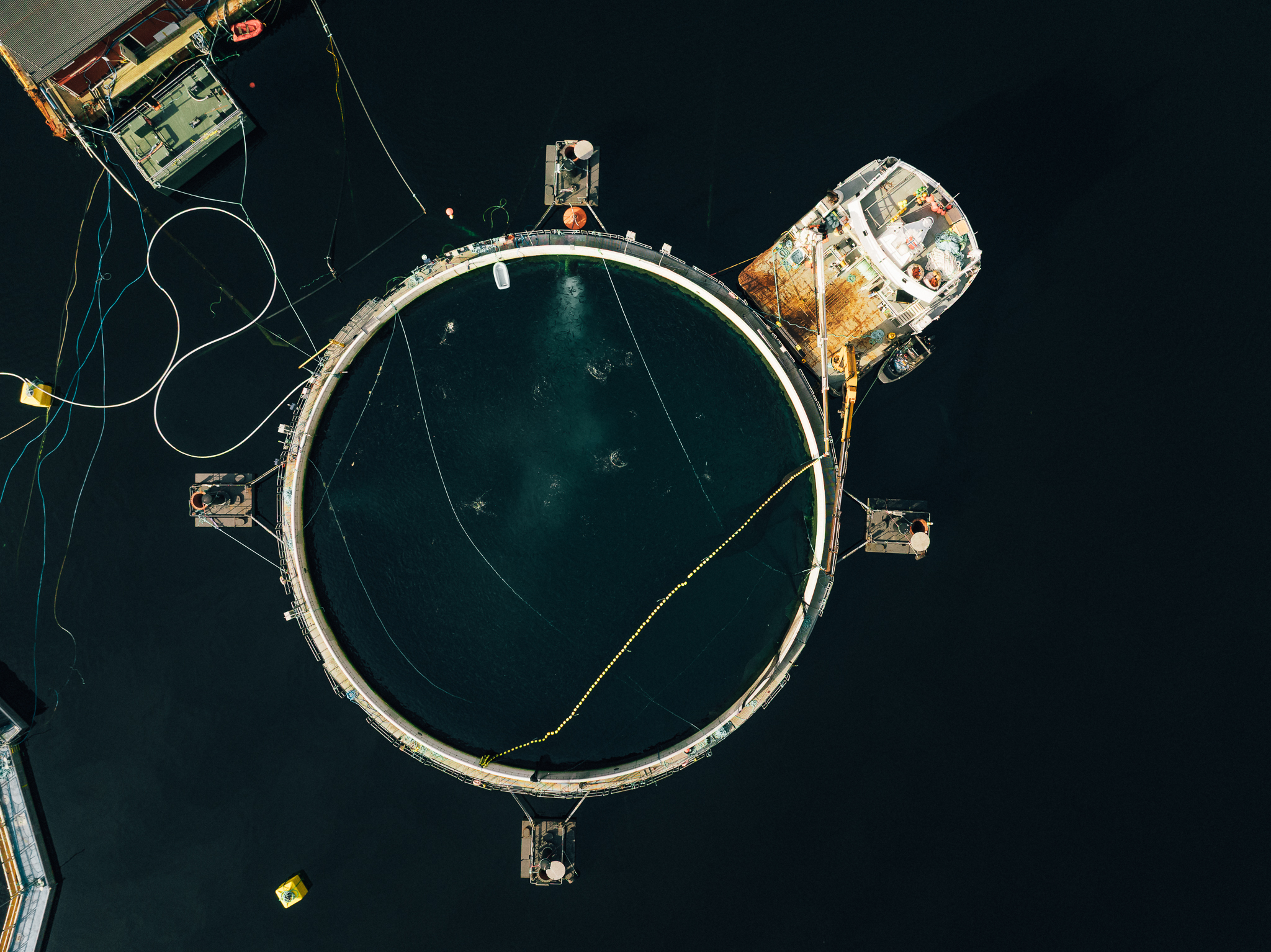

Among the most promising innovations are closed-containment systems – solutions that combine strong fish welfare with reduced environmental impact and greater operational stability. Aquafarm Equipment’s floating semi-closed system is already proving that these benefits are achievable at scale, even in challenging marine conditions.

A Global Shift Toward Smarter Farming

Around the world, countries are introducing measures to safeguard wild stocks and improve sustainability.

- In Canada, the government has announced a gradual transition from open-net pen farming in British Columbia toward systems with stronger environmental safeguards, such as closed and land-based facilities.

- In Chile, new proposals aim to reduce seabed impact by improving sediment management on farm sites.

- In Scotland, the Loch Long Salmon project has received approval for the country’s first semi-closed farm – a milestone for innovation in the region.

These examples show a shared momentum: producers and regulators are working together to find solutions that balance production, fish health, and environmental care.

Why Closed Systems Are Gaining Ground

1. Operational Control

With continuous monitoring of temperature, oxygen, and CO₂, farmers can respond quickly to changes and maintain optimal growth conditions. The system’s modular design allows flexibility in stocking and feeding strategies, adapting to seasonal and site-specific needs.

2. Biosecurity & Fish Health

By drawing clean water from deeper, cooler layers, closed systems can help reduce exposure to parasites and pathogens. Aquafarm Equipment’s deep-water intake, together with controlled oxygen levels, supports more stable conditions and can lower the need for treatments – contributing to healthier fish and improved growth rates.

3. Environmental Performance

Waste capture is built into Aquafarm’s design, preventing feed residue and organic material from impacting the seabed. This helps maintain good local water quality and aligns with emerging sustainability goals across the industry.

Balancing Investment and Return

While building a closed-containment system requires higher initial investment than an open-net pen, many farmers find operational costs comparable over time. Improved survival rates, reduced treatment needs, and the ability to meet premium market requirements can strengthen long-term profitability.

Aquafarm’s projects, from Lofoten to NEOM in Saudi Arabia, demonstrate how well-designed technology can deliver results in both cold and warm-water environments – offering a reliable platform for sustainable growth.

Moving forward

As aquaculture continues to develop, solutions that combine environmental care with strong production performance are becoming central to the industry’s future. Closed-containment technology offers a practical, field-proven way to meet these expectations – and Aquafarm Equipment is committed to supporting farmers in that transition.

When you also consider lower mortality, fewer treatment costs, and improved survival rates, closed systems may provide better long-term profitability, especially in regions with strong sustainability premiums or regulatory incentives.

Balancing Investment and Return

Aquafarm Equipment’s system is a floating semi-closed-containment cage built from fiberglass-reinforced plastic and designed to perform in exposed coastal and offshore environments. It combines deep-water intake, and robust modular design to help farmers meet rising environmental and operational demands.

Our cages are already being deployed in projects like NEOM in Saudi Arabia, where scalable, low-impact aquaculture solutions are key to achieving food security goals under extreme environmental conditions.

As aquaculture faces increasing scrutiny – from regulators, investors, and consumers – closed-containment systems are no longer just a theoretical option. They are an actionable, future-ready solution for operators seeking growth through control, sustainability, and compliance.