Ydra x Aquafarm Equipment: Engineering the Heart of Our Water Systems

Aquafarm Equipment builds for demanding waters, where reliability, uptime, and day-to-day serviceability decide performance. That’s why we partnered with Ydra to co-engineer the core of our onboard water systems; robust mechanics, VFD control, and long service life tuned to real farming. Ydra supplies the pumping system and the engineering that ties it together: pumps, electric motors, and frequency converters supported by design work, CFD analysis, and 3D drawings.

— We deliver the heart of the onboard water systems, paired with the design and analysis to make them work day to day, explains Petter Laugerud (Regional Manager at Ydra Stavanger).

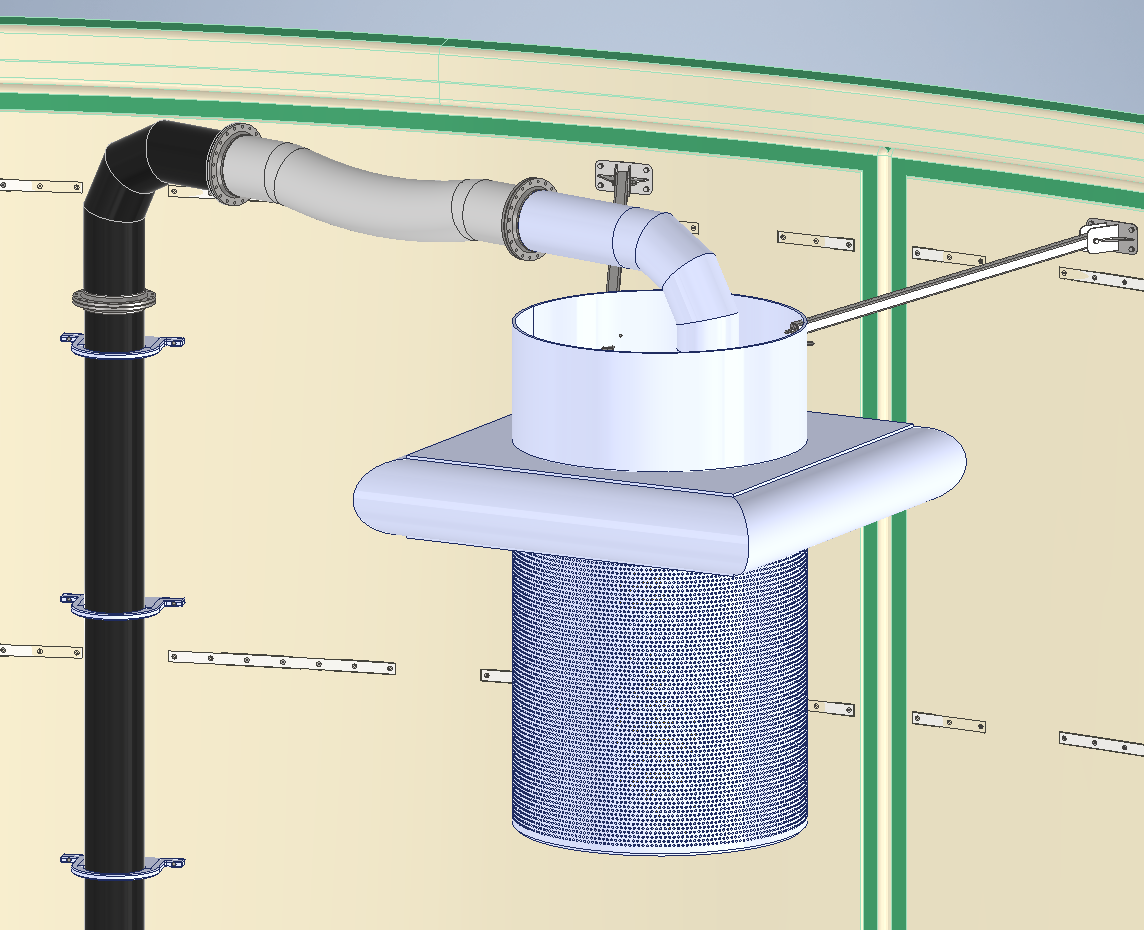

In close dialogue with our team, Ydra developed a high-efficiency propeller pump in corrosion-resistant materials for intake duties, and a floating cleaning module with an integrated pump and piping to keep cages clear and flow stable, both built for robustness and service life under Ydra’s principle “Built to Last”.

Why this partnership works

From day one, our teams aligned on what matters offshore: quality, operational reliability, and predictable operations in tough conditions. That common ground drives choices from materials and sealing to maintenance access and control logic, and it’s central to scaling cleaner, semi-closed production.

Laugerud explains our partnership like this: — Aquafarm were clear about quality and operational reliability in tough conditions; that plays to our strengths. It’s about robust solutions, sustainable choices, and predictability for the customer.

From design gates to the test rig; what we proved and how we work

Before heading offshore, the joint team verified hydraulic capacity, efficiency, and service access on the rig to de-risk installation and hand operations a reliable baseline. The outcome matched specification and gave us the confidence to scale across phases and sites. Pumps delivered as specified on capacity and efficiency.

Execution follows the same discipline: defined design gates, tight feedback loops, and clear role ownership across both companies. Laugerud explains the process:

– Ydra’s project manager tracks installation milestones in close dialogue with our delivery team so decisions stay tied to operating reality. When adjustments are needed, we tune details quickly, but always within lifetime targets set up front. Iteration is expected; robustness and quality are non-negotiable.

What’s next?

With engineering complete, the program shifts into installation and field verification through late autumn and spring. The first intake units are queued for commissioning, and performance will be measured against the outcomes that matter most to farmers: energy-efficient hydraulics, predictable operations, and cleaner production. — The first batch of intake pumps is ready, with installation planned through late autumn and spring, Laugerud says. And as he puts it, the bar is high by design: —Aquafarm sets the standard high, and we like that. Together we’re building solutions for demanding conditions.

We are grateful to have a partner like Ydra on this program; their engineering discipline and service mindset help us deliver reliable, cleaner farming at sea.

Interested in technical specifics or a project conversation? Get in touch and we’ll connect you with our engineering team (and Ydra) for a deeper dive into design choices, materials, and field performance.

Join the NEOM watchlist